LEAN TOOLS

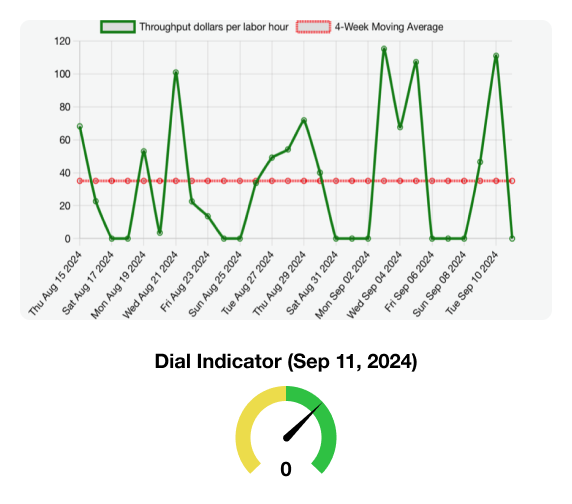

How we use this is to see our performance daily, and provide our team with metrics that help drive decisions in real time

OVER THE LINE CHART

With optional built-in bonus system

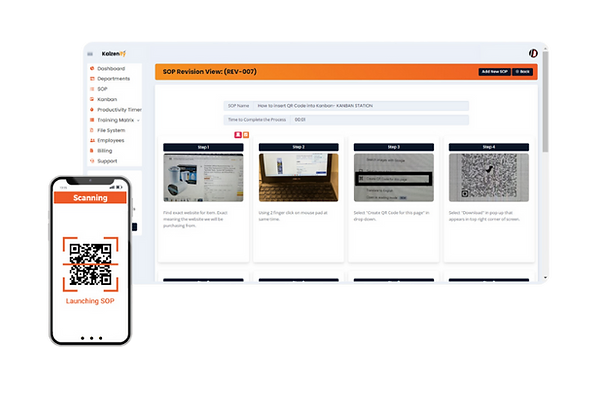

SOP’s

We use SOP’s for machine maintenance, instructions, etc.

Learn More @ Kaizenify.appWhy we use it:

Reduced Errors

Clear instructions minimize mistakes and ensure smoother workflows.

Operational Consistency

The SOP ensures that processes are executed uniformly across teams and shifts.

Consistent Product Quality

Standardized procedures lead to higher-quality products with fewer defects.

Efficient Employee Training

Onboarding is faster with a simple, easy-to-follow guide for new hires.

KANBAN

Kanban has streamlined our inventory management.

Learn More @ Kaizenify.appWhy we use it:

Optimize Inventory Control

Avoid overproduction and stock shortages by maintaining just the right level of inventory with Kanban’s real-time signals.

Simplify Purchasing

All information to make a purchase is readily available to make it happen.

Forces Organization

Prints shelf labels and and crumb trail cards at the same time.

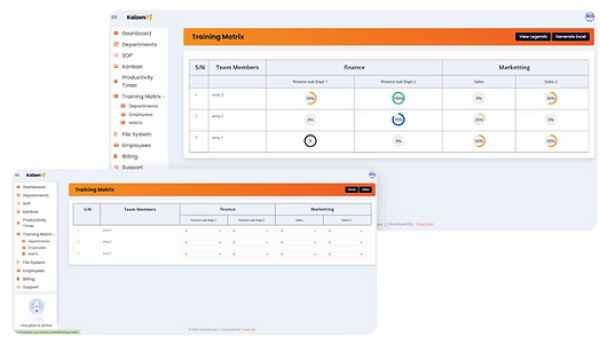

TRAINING MATRIX

Keeps track of who-knows-what’ factory wide.

Learn More @ Kaizenify.appWhy we use it:

Skill Management

Tracks employees' skills and training needs to identify gaps and boost performance.

Compliancy and Safety

Ensures employees meet regulatory and safety training requirements.

Resource Allocation

Helps plan and allocate resources efficiently based on training and skills.

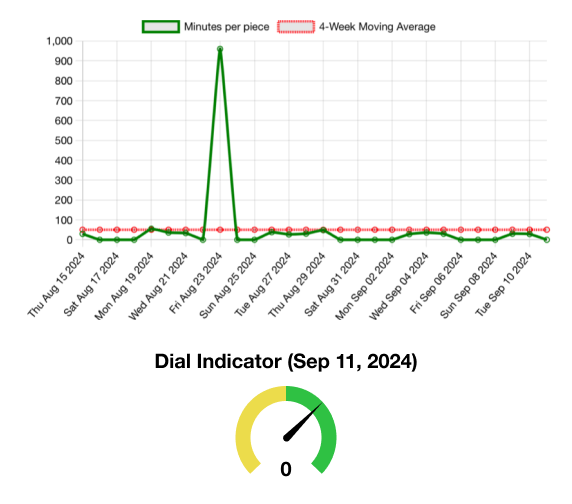

ANDON/CYCLE TIMERS

We can now measure production cycles to predict costs, leadtimes, and measure efficiency gaps.

Learn More @ Kaizenify.appWhy we use it:

Enhanced Efficiency

Provides real-time alerts and tracks production times, helping to quickly address issues and optimize processes.

Improved Quality Control

Enables prompt intervention for quality issues and highlights deviations in cycle times, ensuring higher product standards.

Increased Worker Engagement

Promotes transparency and sets clear performance goals, encouraging proactive problem-solving and improved worker motivation.